This is the first time that Eco Power has supplied a Finnish electric boat manufacturer with a complete traction system for an electric boat. In the summer, many Finns are keen on camping and other outdoor activities. Helsinki's beautiful coast and island scenery attracts a large number of visitors. Emission-free electric boats as a new option for water transportation will bring more convenience to the public and the tourism industry. The local electric boat manufacturer invited Eco Power to participate in the project because of Eco Power's extensive experience in electrifying traction systems. Throughout the course of the project, the two parties established a good working relationship.

Following the electrification, the vessel underwent a complete reconfiguration of the engine room and the removal of the diesel-powered hydraulic motor and old control system. eco Power provided two DC/AC inverters for motor control, a DC/DC converter for 24VDC power and battery control, and an AC/DC rectifier for AC grid connection and a zero-emissions electric drive power assembly system. With this proven technology, the customer has the first all-electric passenger ship.

The electric ship is powered by lithium-ion power cells. This new power system not only increases redundancy but can also be used for one or two motors. Since more power is needed in icy conditions, the motors can be maintained on a rotating basis without suspending the ship's operation. DC/DC converters can increase the battery voltage and make it the same as the motor inverter to minimize energy loss while maximizing performance and reliability.

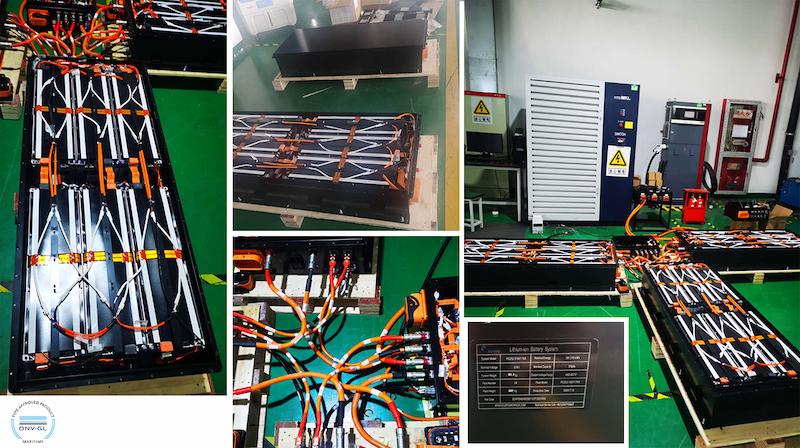

The whole boat is equipped with two motors placed on each side of the boat, so the power system is also divided into two sets, placed on the left and right sides. The single side system is equipped with 1 PDU and 3 battery packs, each equipped with 176Ah battery cells and 1 parallel 60 strings (576V176Ah/101KWh). In total the two power systems are also configured in parallel, which would be 576V352Ah / 202KWh. Energy consumption is less than 3 kWh per hour, compared to the previous diesel ferries which consumed about 2 liters of fuel in the same time period. This will mean significant cost savings as the annual energy cost of the ferry is equivalent to the cost of two months of diesel fuel.

The electric boat is expected to be in service by October 2020 and will cost significantly less as it will no longer use diesel fuel. At the same time, energy consumption will be reduced due to the lighter weight. With fewer power components, the carbon emissions and maintenance requirements of electric boats will be reduced accordingly. The motor bearings are the only two wear parts that are specifically designed to match the life of the motor.

Drivers and visitors can enjoy fresher air because there are no more fumes from the ship's diesel engines due to the new energy sources utilized. The electric ferry maintains the same feel as a chain drive but becomes quieter and weighs four tons less, resulting in increased efficiency and easier maintenance. The traction system supplied by Eco Power has passed the functional tests, environmental tests and thermal propagation tests required for DNV certification and has received the relevant certification from DNV.